10 bestDie Cutting Machinesof February 2026

112M consumers helped this year.

1

Cricut Explore 4 Essentials Bundle

Cricut

9.9

7% off

2

Cricut Maker 4 Smart Cutting Machine

Cricut

9.8

10% off

3

Cricut Joy Xtra | Smart Cutting Machine Starter Bundle | 2025

Cricut

9.6

4

Cricut Explore 3 | Starter Bundle (2024)

Cricut

9.3

5

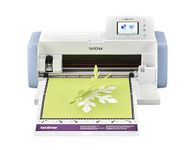

Brother SDX2250D Scan n' Cut Electronic Cutting Machine.

Brother

9.0

OtherUp to 12% off

7% off

6

Cricut Joy | Starter Bundle (2025)

Cricut

8.7

7

Brother ScanNCut CM300 Home Cutting Machine, Off White

Brother

8.5

8

Brother ScanNCut SDX900 Home Cutting Machine, Red and White

Brother

8.2

9

Cricut Maker 3

Cricut

7.9

10

Cricut Smart Cutting Machine (Peacock Blue), Vinyl, Explore Air 2 | 2024 Limited Edition

Cricut

7.6

A Guide to Selecting the Best Die Cutting Machines

Choosing the right die-cutting machine can be a game-changer for your crafting projects. Whether you're a hobbyist or a professional, the right machine can help you achieve precise cuts and intricate designs with ease. To make an informed decision, it's important to understand the key specifications and how they align with your needs. Here’s a guide to help you navigate through the essential features of die-cutting machines.

Cutting Width

Cutting width refers to the maximum width of material that the machine can handle. This is important because it determines the size of the projects you can work on. Machines with a smaller cutting width (around 6 inches) are suitable for card-making and small crafts, while those with a larger cutting width (12 inches or more) are better for scrapbooking, larger projects, and professional use. Choose a cutting width based on the typical size of your projects.

Cutting Force

Cutting force is the pressure the machine applies to cut through materials. This is crucial for working with different types of materials. Machines with lower cutting force (around 200 grams) are ideal for paper and thin materials, while those with higher cutting force (up to 1000 grams or more) can handle thicker materials like leather, fabric, and chipboard. Consider the types of materials you plan to use most frequently when selecting the cutting force.

Compatibility with Materials

Compatibility with materials refers to the range of materials the machine can cut. Some machines are designed to cut only paper and cardstock, while others can handle a variety of materials including vinyl, fabric, leather, and even thin wood. If you plan to work with diverse materials, look for a machine that offers broad compatibility. This will give you more flexibility in your projects.

Ease of Use

Ease of use encompasses how user-friendly the machine is, including setup, operation, and maintenance. Some machines come with intuitive software, clear instructions, and easy-to-navigate controls, making them ideal for beginners. Others may have a steeper learning curve but offer more advanced features for experienced users. Consider your comfort level with technology and how much time you’re willing to invest in learning to use the machine.

Portability

Portability refers to how easy it is to move and store the machine. If you have limited space or plan to take your machine to crafting events, a lightweight and compact model might be best. However, if you have a dedicated crafting space and don’t need to move the machine often, a larger, more robust model could be more suitable. Think about where and how you’ll be using the machine to determine the importance of portability.

Software and Design Options

Software and design options pertain to the digital tools and design libraries that come with the machine. Some machines offer extensive design libraries and user-friendly software that allows you to create custom designs. Others may have limited design options or require additional purchases for software. If you enjoy creating unique designs or need a wide variety of templates, look for machines with comprehensive software and design capabilities.

Manual vs. Electronic

Manual vs. electronic refers to the type of operation the machine uses. Manual die-cutting machines require physical effort to operate, making them simple and reliable, but potentially tiring for large projects. Electronic machines use motors and software to automate the cutting process, offering precision and ease of use, but they require a power source and may be more expensive. Consider your preference for manual effort versus automation when choosing between these types.

Best Reviews Guide Newsletter

Get exclusive articles, recommendations, shopping tips, and sales alerts

Sign up for our newsletter to receive weekly recommendations about seasonal and trendy products

Thank you for subscribing!

By submitting your email address you agree to our Terms and Conditions and Privacy Policy